METAL SURFACE TREATMENT CHEMICALS

It removes all kinds of dirt, oil residues and dusts formed on the surface of the metal and metal parts from the metal surface. They are powder and liquid products used by dipping and spraying methods. It also contains nonionic surfactants used in immersion and spray degreasing baths to add to the degreasing effect.

- Acidic Degreasing Chemicals

- Alkali Degreasing Chemicals

- Neutral Degreasing Chemicalsı

- Aluminum Surface Degreasing Chemicalsı

- Multimetal Oil Receivers

- Electric Degreasing Chemicals

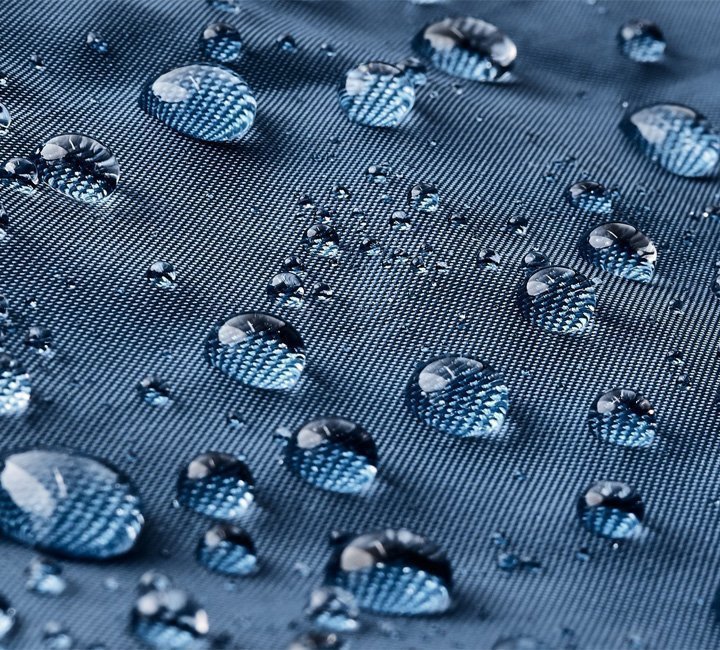

Surface treatment products that provide very good adhesion and corrosion resistance for organic coatings by forming a nano-sized thin film layer on metal surfaces thanks to the special components it contains. Phosphate and VOC (volatile organic compounds) free nano coating chemical, one-step cleaning and nano coating chemical for steel, zinc, aluminum surfaces.

- Zirconium Based Chemicals

The phosphate layer formed on the metal surface provides very good adhesion, corrosion resistance and friction coefficient regulation for paints and organic coatings.

- Iron Phosphate Chemical

- Zinc Phosphate Chemical

- Mono Cation

- DI Cation

- Tri Cation

- Manganese Phosphate Chemical

Surface treatment products that provide good adhesion and corrosion resistance by forming a thin film layer on aluminum surfaces and used in pre-paint preparation.

- Green Chromating (Cr+3)

- Yellow Chromating (Cr+6)

- Transparent Chromating

- Chromium Free

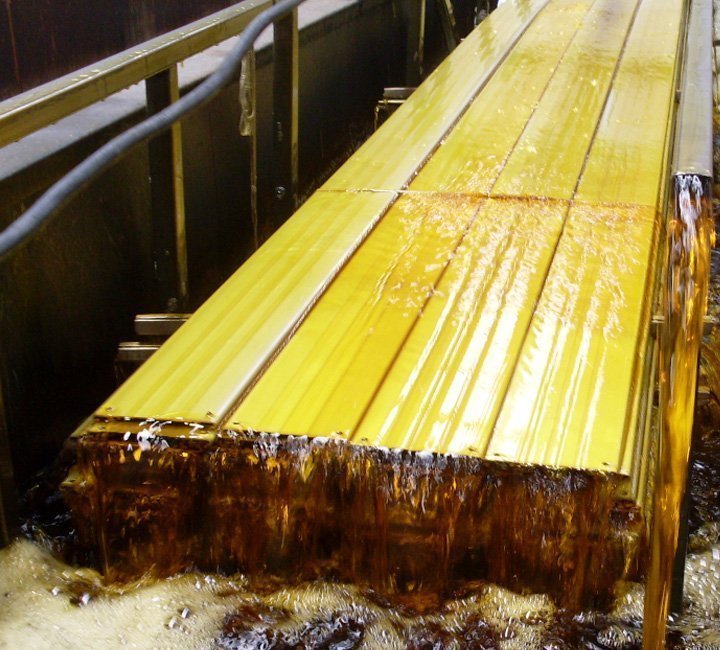

Iron and steel materials are corroded by being affected by the environment they are in over time. With the Hot Dip Galvanizing process, zinc coating is made in a long-lasting way.

- Acidic Degreasing

- Flaks

- Gas Cutter

- Foaming products

- Inhibitor

- Passivation

Products used to prevent rusting in intermediate processes of iron and steel materials and after coating.

- Passivation chemicals used before enamel coating.

- Chemicals used before painting, (Cr+3, Cr+6 and Chromium Free Passivation).

- Protective passivation chemicals used after phosphate coating..

- Passivation chemicals used in intermediate processes and for Sealing Test

- Protective Oil

- Cooling Cutting Fluid

Liquids used in cold forming, deep drawing and pressing of iron and steel materials

- Welding Spatter Preventer

It is a product used in Rotofinish machines/vibrator systems for surface smoothing, rounding corners and polishing, especially on iron parts.